Waste Oil Recycling and Reusing

COMPLETE

Regeneration Kit

1000 L

From 19500 $

Recycling and reusing used motor oil is preferable to disposal and can have significant environmental advantages. Used motor oil can be re-refined into new oil, processed into fuel oil, and used as a raw material in the petroleum industry.

If used oil, such as engine lubrication oil, hydraulic fluid, and gear oil, is not recycled or disposed of properly, it can pollute the environment. To avoid contaminating the environment, used oil must be properly managed by local waste management authorities or automotive repair shops. Similar waste issues arise when used oil filters are discarded. They can be safely recycled or disposed of if properly drained.

Among the numerous reasons to reuse and recycle used oil are:

- Recycling used oil keeps it from polluting the environment and water.

- Motor oil does not wear out; it simply becomes dirty. As a result, recycling it conserves a valuable resource.

- A gallon of re-refined base stock requires less energy to produce than a gallon of crude oil base stock.

Used oil can be refined again into lubricant, processed into fuel oil, and used as a raw material in the refining and petrochemical industries. Furthermore, used oil filters contain reusable scrap metal that steel producers can repurpose as scrap feed.

So, how exactly is used oil recycled? Re-refined oil, the preferred option, must meet the same stringent refining, compounding, and performance standards as virgin oil for use in automotive, heavy-duty diesel, and other internal combustion engines, as well as hydraulic fluid and gear oil. Further laboratory testing and field studies have concluded that re-refined oil is equivalent to virgin oil; it passes all prescribed tests and, in some cases, outperforms virgin oil.

Because re-refining simply re-processes used oil into new, high-quality lubricating oil, the same consumers and businesses who use regular oil can also use re-refined oil. Re-refined oil can be used by any vehicle maintenance facility, automobile owner, or other machinery maintenance operation that uses oil. Some fleet maintenance facilities that use a large amount of oil arrange to reuse the same oil that they send to be re-refined – a true closed recycling loop.

Conclusion

Improperly disposed used oils can be hazardous to the environment and surrounding bodies of water. It takes special skills and expertise to properly manage used oil, as well as recycle it for reuse. With Triboregen-oil you can do it the right way, the simplest and most economical for any entrepreneur without exception.

Our commitment is from producing 2,000 Liters to 10,000 Liters per day and more…!

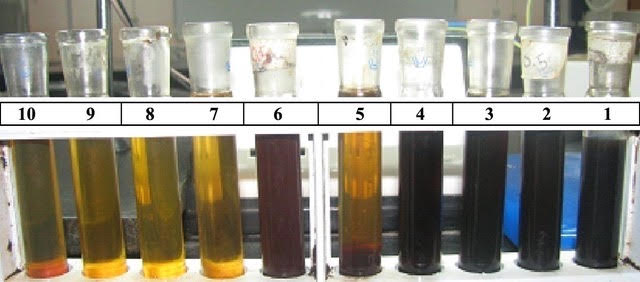

Before / After

A series of laboratory tests on TriboREGEN® additive, with excellent results.

- Number 1 : Waste engine oil to be regenerate.

- Number 2 to 6 : used engine oil treated by different outdated methods sometimes banned causing serious damage to the environment

- Numbers 7 & 8 efficient method with better cost compared to all others. 7 and 8 are the same result as TriboREGEN-Oil

- Number 9 is base oil for fixing « RAVENOL » full synthetic good engine oil.

- Number 10 Using waste engine oil to obtain base oil is the result of Vacuum Distillation Machinery the more expensive equipment requiring high energy consumption plus adding chemical solvent or a clay treatment.